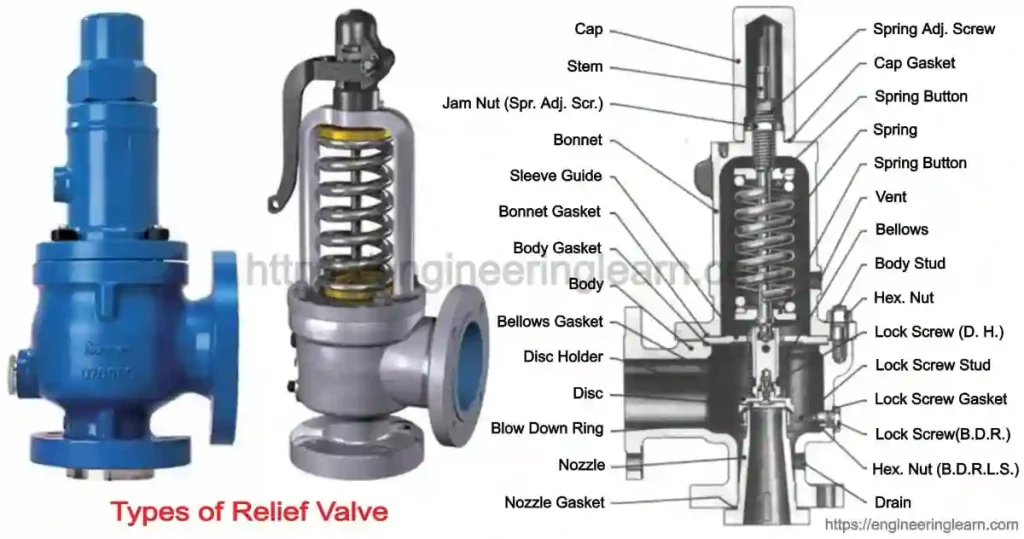

At times, an over-compressed pipeline, pressure vessel, or siphon could be the justification behind serious harm. High-pressure help valves are planned and introduced to prevent such bursts from harming a framework or site. Applications, including fluids or gases, could profit from the utilization of such valves.

The valves can be acclimated to a specific pressure point. Thus, if the pressure penetrates its set point, the valve will permit the over-compressed steam, gas, or fluid to move through a little opening to forestall a complete framework disappointment or blast. Thus, the stable innovation of hydrodynamics has kept on progressing.

It offers engineers adaptable and dependable intends to perform assignments where high payloads and the exact development or freight and materials are needed in continuous work concentrated circumstances, for example, at shipping bays, high on high rises, and different areas with different techniques would be close to inconceivable.

As the inside pressure in the framework lessens or standardizes, activities can be continued in the wake of resetting or supplanting the pressure alleviation valve.

The size of such a valve could go from a couple of crawls to a few feet relying on the size of the tasks. With the utilization of the right valve, terrible occasions, for example, unintentional blast inferable from high pressure, can be forestalled.

Here are some positive credits of high-pressure alleviation valves:

- Establishment: Such valves mustn’t be difficult to introduce. Commonly, you would discover valves that accompany an association end or strung finish to coordinate them into your tasks. The pressure rating of these valves is a vital factor to consider during the establishment stage. Valves are generally accessible, with pressure appraisals going from 500PSI to 10,000PSI.

- Changing pressure settings: The market offers an extraordinary assortment of burst pin-based valves that are exceptionally simple to utilize. If the pressure levels have been penetrated and there is harm to the valve, a straightforward visual investigation will be sufficient to recognize it. Such valves can also be fitted with discretionary components, for example, a pin defender confine, a closeness sensor, and a flush port that helps clear lost dissemination material before resetting.

- Upkeep and substitution: Sometimes, support and substitution cannot exclusively be a restrictively costly interaction. However, they can also be very tedious. It is feasible to change the pressure levels of the valve by changing the size of break pins. Valves dependent on such burst pin innovation are not difficult to keep up with when contrasted with a broken circle or different sorts of spring valves.

- Expenses: Most endeavors can’t easily overlook the expense part of a pressure help valve. The high support and substitution expenses of burst plates and spring valves don’t generally bode well. In actuality, high-pressure help valves dependent on the break pin innovation are a one-time venture that doesn’t cause rehashed upkeep and substitution costs.

Cycles, for example, water-driven breaking, hardcore boring, and mud and slurry tasks utilize such valves. A valve that is utilized in high-pressure boring tasks is alluded to as a penetrating valve.